In the ramp-up to more widespread renewable energy use, thermal energy storage is becoming a go-to solution for enabling power grids to respond to variable supply and demand conditions. When demand is high and solar or wind energy are not available, stored energy could answer the call, and keep the United States moving in a greener direction.

Thermal energy storage systems are like batteries that use temperature shifts to store energy for later use or for use at another location. Such systems capture energy in different ways, and the most commonly used techniques are based on latent and sensible heat transfers. The latent heat method involves using the amount of thermal energy needed for a phase change―which is a change in physical state, such as from solid to liquid, or liquid to gas―without altering a material’s temperature. Sensible heat is the thermal energy required to raise the temperature of a material without causing any phase transitions.

One of the benefits of the latent heat transfer technique is that it enables large amounts of heat to be stored and transferred. In other words, latent heat storage systems are associated with large energy densities. A major advantage of the sensible heat transfer technique is its low cost; however, it relies on large temperature changes to convey large rates of heat transfer.

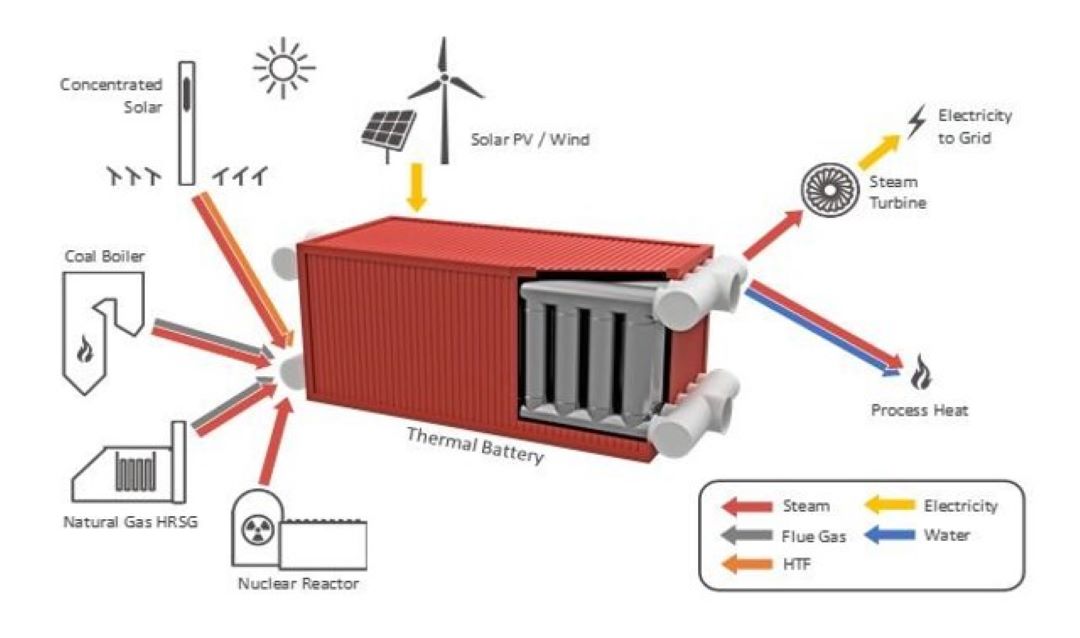

Now, Lehigh engineers, with support from the Department of Energy, have developed a new thermal energy system, the Lehigh Thermal Battery, which combines the best of both techniques. The technology consists of engineered cementitious materials and thermosiphons in a combination that enables fast and efficient thermal performance at low cost. The technology is capable of operating with heat or electricity as the charging energy input. The team has announced that, after three years of research and development, the technology is scalable and market-ready.

The project is a collaboration between Lehigh’s Energy Research Center, Lehigh’s Advanced Technology for Large Structural Systems (ATLSS) Engineering Research Center and Advanced Cooling Technologies.

“The concrete plus thermosiphon concept is unique and new among heat energy storage concepts,” says Carlos Romero, co-principal investigator on the project and director of the Energy Research Center at Lehigh. “The technology offers the potential for adaptation over a broad range of temperatures, and heat transfer media and operating conditions. This makes it suitable for decarbonization opportunities in industry, the flexibilization of conventional power plants, and advancements and penetration of concentrated solar power.”

“The Lehigh Thermal Battery technology is innovative because it is modular, designed for independent energy input/output streams during charging/discharging which is feasible with the help of the thermosyphons, and the two-phase change process inside the thermosyphon tubes allows rapid isothermal heat transfer to/from the storage media at very high heat transfer coefficients and heat rates,” says Co-Principal Investigator Sudhakar Neti, professor emeritus in the Department of Mechanics and Mechanical Engineering at Lehigh.