Seemingly miraculous innovations have made it possible to slake the ever-growing thirsts of our industrial society.

Need more energy? Frack it from deep-bedded rocks.

Fresh water? Desalinate ocean flows.

Precious metals? Leach them from low-grade ores that were previously unminable.

But these and other marvels leave us in a pickle—awash in a sea of hypersaline brine. This “brine”—wastewater containing levels of salt many times higher than seawater and often contaminated with pollutants—is a byproduct of these and other industrial processes, and it’s a problem.

“The disposal of brine solutions with total dissolved solids greater than 60,000 mg l−1 poses technical, environmental and economic hurdles that remain mostly unresolved,” said Arup SenGupta, P.C. Rossin Professor of Civil & Environmental Engineering at Lehigh University.

However, a new approach developed by SenGupta and visiting researcher Hao Chen (then a doctoral student) represents a leap forward in cleaning up and even potentially unlocking valuable resources lurking in the super-salty water.

Current Methods

The current methods of dealing with this byproduct often compound environmental damage inherent in industrial processes.

- Pumping hypersaline brine back into the ocean is a common practice in coastal desalination plants, but doing so can disrupt deep-sea ecosystems.

- Wastewater from inland industrial facilities is often left to evaporate under the sun in massive, open pools, but this process is inefficient, weather-dependent, and prone to the concentration of contaminants that threaten both groundwater and surrounding environments.

- Pumping brine into deep wells within the earth was a common practice but has been outlawed in many areas due to the ecological and geological damage it causes.

- Other methods such as multistage thermal distillation and membrane distillation have some advantages but also require large energy inputs to generate heat and are prone to the buildup of scale and irreversible fouling, or contamination on equipment.

Developing methods for concentrating brine to levels conducive to the collection of crystallized solids has been made a priority of the U.S. Department of the Interior and other global water agencies.

Crystallized solids can more easily be disposed of, re-used for industrial processes and even “mined” for precious metals including lithium.

A New Solution

SenGupta and Chen have developed a new process, evaporative ion exchange (EIX), to concentrate brine at room temperature using air humidity and ion exchange. Unlike existing methods, EIX avoids scaling and fouling, and it's much faster than natural evaporation due to its efficient design. The process is outlined in a study recently published in the journal Nature Water.

It uses a polymeric ion exchange resin bead, a type of gel with a high concentration of charged functional groups, or atoms whose electrical charge binds with ions of opposite charge. When the bead comes into contact with water, the resin's internal pressure causes it to absorb water quickly while rejecting salts and other compounds.

“This phenomenon is similar to forward osmosis, but no semipermeable membrane physically exists. Instead, the ion exchanger-water interface acts as a semipermeable membrane and the water uptake is very rapid,” SenGupta said.

When then exposed to dry air, the resin releases water into the air through evaporation at room temperature without the need for external heat input.

“This cycle can be repeated, allowing the resin to continuously concentrate solutions at ambient temperature,” SenGupta said. “The process is rapid, and the total energy requirement is provided by the ambient air.”

The base resin used in the study was Purolite A502P, a commercially available ion exchange resin for drinking water systems. The researchers doped the material with zirconium dioxide (ZrO2) nanoparticles to ensure its specific gravity and to prevent the resin from floating.

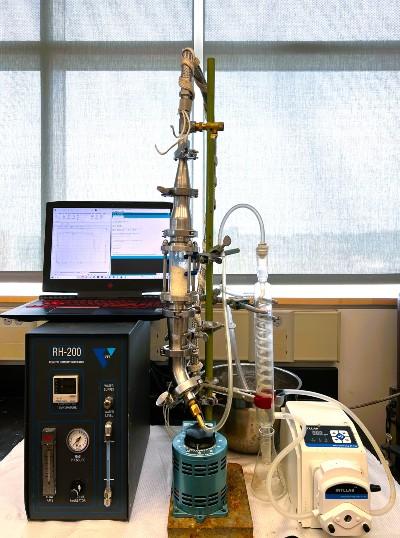

The Experiment

To test the process, researchers conducted experiments using both laboratory-created synthetic hypersaline brine and hypersaline water collected from gas well sites in the Pennsylvania and New Jersey Marcellus Shale region. In addition to salt, the Marcellus sample contained high concentrations of barium cations, strontium cations and calcium ions.

The EIX beads were placed in a bed, which was then filled with brine until the resin reached saturation. The bed was drained of brine, and then resin was exposed to blown, unheated air for evaporation, and the total volume and the total dissolved solids (TDS) of the remaining brine were measured. This cycle was then repeated using the remaining brine.

- After the completion of three cycles, the volume of the remaining synthetic brine was decreased by a factor of nearly three, and the TDS of the remaining synthetic brine was increased by a factor of nearly three.

- Cycles carried out with identical polymer beads but with no ion exchange functional groups achieved an increase in the synthetic brine’s TDS of less than 20%.

- After four cycles carried out with the Marcellus sample, the concentrations of barium, sodium, and chlorine were concentrated beyond the solubility limit, resulting in direct crystallization of barium chloride and sodium chloride salts.

- The processes did not result in scaling or fouling of the resin, and the experiments indicated the ability to concentrate and recover lithium from naturally occurring hyperbrine.

“The most remarkable finding of this study is the precipitation/crystallization of salts from the hypersaline water from a Marcellus gas well after four EIX cycles at ambient temperature,” SenGupta said. “According to the literature, no other brine concentration process attains incipient crystallization at ambient temperature.”

The study was completed with grant funding from the U.S. Bureau of Reclamation, the Pennsylvania Infrastructure Technology Alliance and a Lehigh faculty innovation grant.

Looking Ahead

SenGupta said the process’s advantages make him optimistic about the potential for the process to be scaled up for widespread use.

The next steps would be to run a pilot system and record its process parameters and energy advantages compared to other elevated temperature processes.

“The EIX process does not need any specialty material to be manufactured for scale-up of

the process,” SenGupta said. “It does not need any heat or major energy source. It can be rapidly scaled up.”

Story by Dan Armstrong