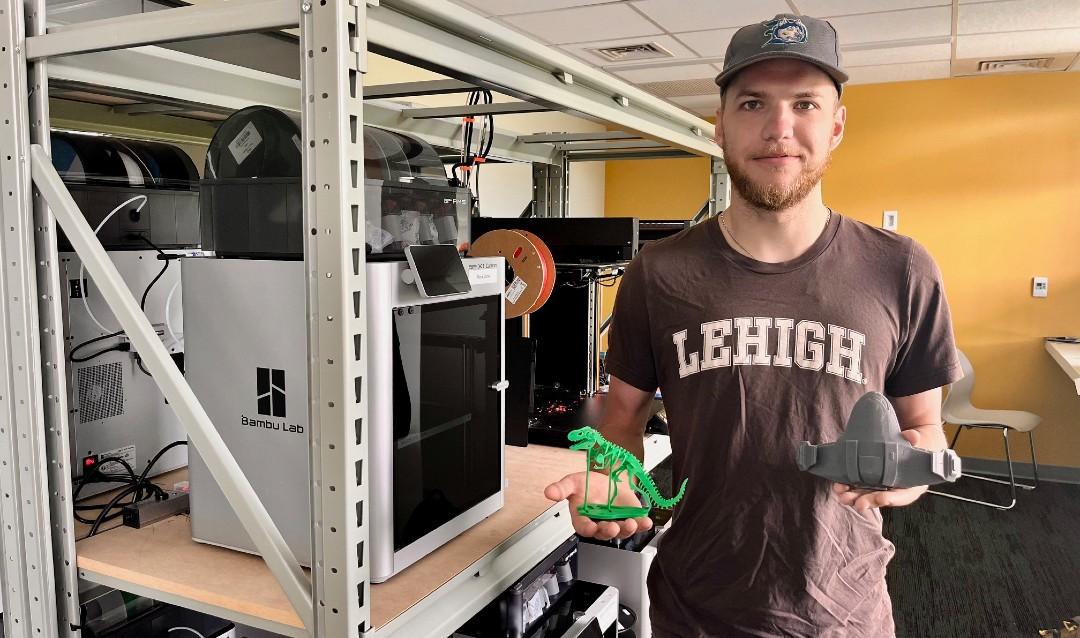

To meet the growing demand for 3D printing resources, Lehigh's Design Labs has established a new 3D printing hub on the Mountaintop campus. Located in Building C’s 'crescent' in the former PSECU storefront, the new hub is centrally located making it convenient for those on Mountaintop campus and easy to find.

The 3D printing hub is the newest addition to Design Labs, which boasts five main lab spaces across two locations. In Wilbur, there is the MakerSpace, Additive Manufacturing Lab (3D printing lab) and Electronics Design Studio. Meanwhile, in Building C, the Design Lab operates a woodshop, a metal shop and various digital fabrication technologies, including CNC plasma cutters, CNC routers and laser cutting tools.

“As the Design Labs continue to grow and collaborate with more departments, student clubs, and campus organizations, enhancing hands-on experiential learning across all of Lehigh's colleges, we need to ensure these resources are as available and accessible as possible,” Brian Slocum, director of the Design Labs, says. “Adding this 3D print hub at Mountaintop will complement our existing facilities and make the work flow more efficient to students and faculty who spend most of their time at the Mountaintop campus.”

The hub at the Mountaintop campus joins the existing facilities at Wilbur, which feature 30 networked filament printers, high-resolution SLA printers, a powder bed nylon printer and direct metal printing capabilities. Filament printers, commonly known as FFF (Fused Filament Fabrication) printers, use thermoplastic filaments to create objects layer by layer, while high-resolution SLA (Stereolithography) printers use a laser to cure liquid resin into hardened plastic, providing finer details and smoother finishes. Over its decade-long operation, the 3D printing facilities at Wilbur have accumulated more than 120,000 print hours across 40,000 projects, serving students from various disciplines.