Unraveling the Secrets of Nano-Gold

People have been using metal particles as catalysts for more than 100 years. But for many of those years, no one had considered using gold. Researchers long assumed that gold, a noble metal that doesn’t tarnish, would not serve as a good catalyst.

“Bulk gold such as that used in jewelry, is pretty unreactive. Chemically, it doesn’t do much,” says Chris Kiely, the Harold B. Chambers Senior Professor of Materials Science and Chemical Engineering.

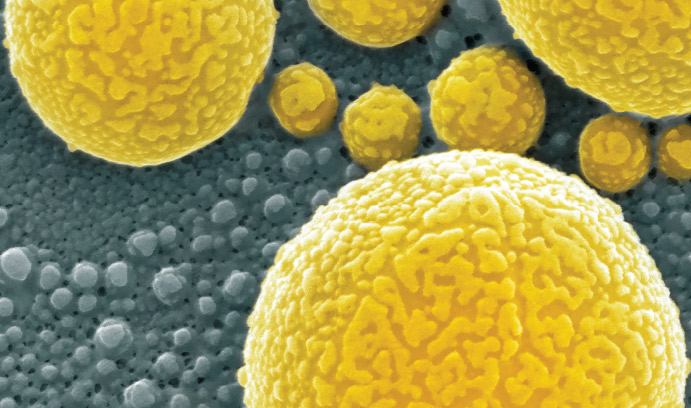

Things changed, however, in the 1980s, when two researchers in different parts of the world—Masatake Haruta, now of Tokyo Metropolitan University, and Graham Hutchings, now at Cardiff University—proposed separately the potential use of gold as a catalyst. As it turns out, making gold with ultra-small dimensions changes its physical properties, turning it into a highly effective catalyst for a number of important chemical reactions.

Kiely has been studying gold catalysis for more than 20 years. He works with colleagues around the globe, including Hutchings and Haruta, to explore the use of different forms of nano-gold for various technological applications.

“We’re getting to the point where we can now precisely control the type of nano-gold that we make,” says Kiely. “The gold could be just individual atoms sprinkled over a support, or it could be tiny little clusters of three or four or five atoms, or it could be larger nanoparticles, or it just could be nanoparticles floating around in a liquid. … Now we’re unraveling which of these forms is good for which reaction.”

Kiely directs Lehigh’s Electron Microscopy and Nanofabrication Facility, which includes instruments such as an aberration-corrected JEOL JEM-ARM200CF scanning transmission electron microscope (STEM), a powerful tool that allows researchers to conduct imaging and chemical analysis of materials at the atomic level. Using these electron microscopes, the Lehigh researchers serve as “the eyes” for collaborators who make the catalyst materials they study.

“[We] work closely with these other folks to find out exactly what they have made and hopefully to point them in the right direction for improving their catalyst manufacturing process,” says Kiely. “Via this feedback loop, where we advise them on what they’re making, they can refine their methods in an informed manner to make just atoms or clusters or nanoparticles [of gold]. We have been effectively embarking on a microscopy-informed catalyst design process, and the next step is to explore the effectiveness of these precisely engineered gold catalysts for different reactions.”

In 2017, Kiely and his team published with international partners three papers in Science, each reporting the results of a different approach to using gold as a catalyst.

The March 2017 report in Science, titled “Identification of single site gold catalysis in acetylene hydrochlorination,” reveals the use of gold as a catalyst in a more environmentally friendly approach to producing vinyl chloride monomer (VCM), a precursor to manufacturing polyvinyl chloride (PVC), a very widely used plastic.

Kiely and his Lehigh team, including doctoral student Li Lu, worked in collaboration with Hutchings and his team at the Cardiff Catalysis Institute at Cardiff University. Kiely and Hutchings both serve as co-directors of the Institute.

VCM is manufactured in large quantities by two main routes, which use either oil or coal as the starting feedstock. A clean process has been developed for the oil-based route. However, when starting from coal, which is the more prevalent feedstock in China, mercury chloride is currently used as a catalyst, which puts mercury, a toxic substance, into the environment. The search for a more environmentally friendly approach has been a priority for some time.

The team used synchrotron-based spectroscopy techniques and advanced electron microscopy to determine that isolated gold ions—that is, individual charged gold atoms dispersed over a carbon support—serve as a catalyst to convert acetylene, a gas derived from coal, to the VCM needed to create PVC, eliminating mercury from the equation.

“The mercury chloride catalyst is not needed anymore, so hopefully Chinese chemical companies will phase it out and move to this highly effective, cleaner, greener gold-based catalyst,” says Kiely.

Kiely and Hutchings, who have collaborated for three decades, reported in an article in Nature Communications in 2016 that for another reaction, namely the low temperature oxidation of carbon monoxide to carbon dioxide, a different gold entity—namely, supported ultra-small clusters consisting of just a few gold atoms—was the most active species.

The encouraging results obtained in both these projects are now spurring Kiely and Hutchings to design and optimize gold-based catalyst systems for use in other important reactions.

Gold for Cleaner Automobiles

Gold plays a role in a potential future option for transportation applications as well.

“Ideally we want to have cleaner automobiles which run on hydrogen, so you have to make that hydrogen fuel somehow,” says Kiely. “However, you need to make it so that it’s pure [and] it doesn’t contain traces of carbon monoxide, which can poison the fuel cell catalyst.”

For years, says Kiely, this was easier said than done.

“You could make active catalysts, which would work okay for a few hours or a few days and then gradually die. You could also make catalysts which would work for a longer time, but they invariably weren’t quite active enough or didn’t get rid of the carbon monoxide contaminant from the hydrogen product stream.”

Working with researchers in China, Kiely and his team found the answer. Once again, gold did the trick, but this time in a different form: raft-like gold nanoparticles on a special type of molybdenum-carbide substrate. The gold catalyst achieved a high level of activity at low temperatures while producing the pure streams of hydrogen necessary to power fuel cells.

The team reported their results in the July 2017 issue of Science in a paper titled “Atomic-layered Au clusters on alpha-molybdenum carbide as catalysts for the low-temperature water-gas shift reaction.”

In addition to Kiely, the paper’s authors include Lu and Wu Zhou, who earned his Ph.D. at Lehigh in 2010 and is now a professor at the University of the Chinese Academy of Sciences in Beijing. Other authors are affiliated with Peking University, Dalian University of Technology, Synfuels China and Taiyuan University of Technology, all in China, and Oak Ridge, Brookhaven and Lawrence Berkeley National Laboratories in the U.S. The lead scientist in the work is Ding Ma, a professor in the College of Chemistry and Molecular Engineering and the College of Engineering at Peking University in Beijing.

The researchers achieved their goal by utilizing the water-gas shift (WGS) reaction, which converts carbon monoxide (CO) and water into hydrogen (H2) and carbon dioxide (CO2). The group was able to purify the hydrogen by using up all available CO, which tends to deactivate fuel-cell catalysts. The WGS reaction, which is typically used to make hydrogen for the manufacture of chemicals like ammonia, is also a critical part of the effort to transition from hydrocarbon-based fuels to hydrogen.

Kiely said the use of gold on the alpha-molybdenum carbide substrate—an innovation by Ma and his colleagues at Peking University—enabled the group to overcome shortcomings previously reported with catalyzing the WGS reaction.

“It has long been known that gold supported on various oxide substrates could bring about the WGS reaction. The sticking point to date has been that generally the catalytic activity was too low and invariably the catalyst was not stable enough for long-term use,” Kiely says.

Methane to Methanol

Liquid methanol is widely used as a feedstock for other chemicals and also has considerable potential as an alternative fuel source. However, converting methane—the primary component of abundant natural gas—into methanol is currently achieved by an indirect process which requires high levels of heat and pressure. Kiely and his team, working again with Hutchings and his team at the Cardiff Catalysis Institute, discovered a new approach that allows the direct conversion of methane to methanol utilizing molecular oxygen under much milder reaction conditions.

Once again, gold was the answer—in yet another form. Here, the team used gold-palladium nanoparticles existing as free-floating colloids in a very weak hydrogen peroxide solution, into which they injected pressurized methane and oxygen gas.

“The new simplified approach we have demonstrated brings us a step closer to making the direct conversion of methane to methanol a practically viable proposition,” says Kiely.

In September 2017, the team led by Kiely and Hutchings published another paper in Science. This one, titled “Aqueous Au-Pd colloids catalyze selective CH4 oxidation to CH3OH with O2 under mild conditions,” demonstrated their promising approach of using colloidal gold-palladium alloy nanoparticles to directly oxidize methane to methanol with high selectivity in aqueous solution at mild temperatures. Other authors include Qian He, who earned his Ph.D. in materials science and engineering from Lehigh in 2013 and is now a University Research Fellow in the School of Chemistry at Cardiff University, and a current Lehigh doctoral student, Sultan Althahban.

“Thirty years ago, people would not have seriously thought about using gold at all in catalysis,” Kiely says. “Now, we’re finding that gold is good for lots of reactions, and we’re getting to the point where we can determine exactly what form of gold is required for specific reactions.”

Posted on: