The Cutting Edge of Additive Manufacturing

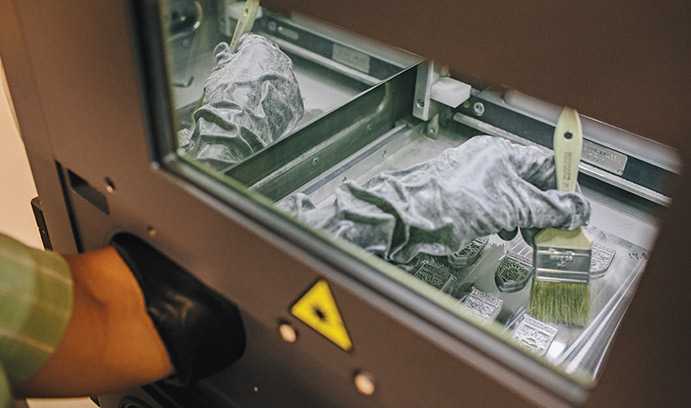

Stainless steel busts of Asa Packer that were printed with Lehigh's new Renishaw 3-D metal printer.

Lehigh expands possibilities with a Renishaw 3-D metal printer.

Some have described 3-D printing, or additive manufacturing, as the third industrial revolution. It allows users to print things that would be almost impossible to make in a traditional machining environment. This summer, Lehigh expanded the possibilities with a Renishaw 3-D metal printer, the second the British engineering company has ever made in its particular series and the first in the United States.

Lehigh acquired the printer through a uniquely comprehensive educational partnership with Renishaw. The industrial platform printer, which has a 400-watt laser and a 250x250x300 millimeter build chamber, employs what’s known as powder bed fusion technology. Any type of metal that can be rendered in powder form is loaded into the material hopper of the machine. An arm within the printer smooths the powder and a laser selectively melts the powder together so it solidifies into a single metal piece. The build plate drops down 50 microns and a new layer of powder is pushed on top of it. The laser returns and selectively melts the next layer, which then melts into the layer below. The process repeats until the desired part is fully formed.

Renishaw is allowing Lehigh to change the machine’s processing parameters as needed for research. Brian Slocum, managing director of Lehigh’s Wilbur Powerhouse and Design Labs and director of the university’s Additive Manufacturing Lab, and doctoral student Trevor Verdonik will visit Renishaw’s headquarters in England to learn how to develop process parameters from the Renishaw side.

Carpenter Technologies, a powdered-metal supplier based in Reading, Pa., will fund research that will assist in their materials development, and multiple research funding agencies and corporations have come calling since learning of the new printer. Renishaw is pushing its client base to Lehigh to conduct research related to end-use products.

“We’ve had [3-D printing] at Lehigh for a long time, way before it was the cool thing to do,” says Slocum. “... Now there’s actually some core scientific research dollars coming in that we can tap into. I think we’re well leveraged to do that.”

Posted on: