Lehigh Students Show their Metal at Industrial History Museum

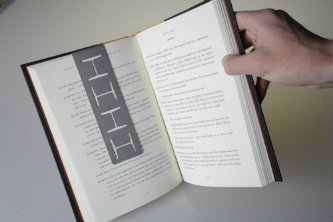

Students' products were featured at a “Meet the Makers” event at the National Museum of Industrial History on Dec. 10. They are now displayed and will be for sale until the end of December in the museum’s gift shop. Photo by Christa Neu.

Inspired by Bethlehem’s steel history and industrial production, a group of Lehigh University students has created unique products for sale this holiday season at the National Museum of Industrial History.

Ranging from candle holders to bookmarks to lamps, the metal-crafted products were designed by students in Lehigh’s Product Design III course taught by Wesley Heiss, artist and associate professor of art, architecture and design.

“Many of the designs were directly inspired by objects in the museum collection or the grounds of Bethlehem Steel,” said Heiss of the goods, which range from whimsical and creative to practical. “Some are great for kids, some are nostalgic and celebrate the industrial heritage of our area,” he said. “Some are slick and modern, some are great accessories for entertaining.”

Students were required to work with folded sheet metal as their primary material, with some also using rubber, wood and 3D-printed components for their designs. Through the class, students visited local fabricators, designers and material suppliers. Most of the products were laser cut and formed at Trexler Industries in Bethlehem Township, with some fabricated by Benco Technology in Honey Brook, Pa., or cut on the waterjet cutter in Lehigh’s Packard Lab.

Products include book lights, shelving, smartphone virtual reality (VR) goggles, candle holders, furniture, candy dishes, serving trays, wine bottle holders, lamps, picture frames, bookends, music boxes and furniture.

The least expensive item is a bottle opener for $6; the most is a chair for $300. Forty percent of sales proceeds go to the museum; 60 percent go to the students to cover their costs in prototyping and fabricating their designs.

Products were featured at a “Meet the Makers” event at the museum on Dec. 10. They are now displayed and will be for sale until the end of December in the museum’s gift shop, or as long as supplies last. Some products were manufactured in quantities of 50 and others are one-of-a-kind.

Housed in the 100-year-old, 40,000-square-foot former Bethlehem Steel Electrical Repair Shop – part of the company’s iconic South Side Bethlehem complex – the museum’s artifacts and exhibits highlight the people, machines and ideas behind Bethlehem Steel and America’s industrial heritage.

The museum, a few blocks from Lehigh, “has an amazing collection of things to inspire students’ designs,” Heiss said.

Through the class, the 13 students learned how to manage deadlines and budgets, take risks, integrate customer feedback, refine ideas through multiple iterations and work with outside fabricators.

Student Andy Freedman ’17, who designed a corkscrew and wine bottle openers displayed at the museum, said he learned how to handle manufacturing challenges, as well as take designs from sketch to three-dimensional models, while developing skills in computer-aided design, woodworking, rendering and other design techniques.

“The program has been difficult and extremely time consuming, but very much so worth it in the end,” he said, proudly describing his wine bottle holders as “beautiful.”

Student Madeleine Wescott ’17 created a candle holder inspired the steel stacks skyline and Bethlehem Steel’s historic impact on the region, as well as a tray based on the arch and circles of the side planer machine on display at the museum.

“Designing a product was something I was used to, but learning how to mass produce a product came with a lot of road bumps,” Wescott said. “I had to constantly be conscious of the different costs that came with manufacturing my product because I wanted to make my products affordable while still breaking even.”

Student Zach Port’s sheet metal bookmarks feature cutouts of I-beams, gears and the museum logo.

“I learned about all the directions you can go when making a product,” Port ’17 said. “This class was an excellent opportunity to bring a product from an idea to a sellable item.”

Noah Saltzman ’17 designed a stool for the class made of bent sheet metal and hand-turned wood that was inspired by the wood patterns used by Bethlehem Steel to cast parts, as well as the interaction of the two materials—the warmth of wood and cold steel.

“I learned what it is like to not only design a product but what it takes to actually produce and manufacture it under real-world constraints, such as a budget and outsourced manufacture,” he said, adding that Lehigh’s product design courses “allow you to explore your creativity while making tangible things, not just concepts and ideas.”

Heiss has been running similar projects with his classes since 2007. Students are tasked with designing, prototyping, testing, outsourcing production, marketing and selling products through a local retailer. In the past, students have sold their designs through Home and Planet in Bethlehem and Mercantile Home in Easton.

This year’s students rose to the occasion.

“Working with metal is a challenge and the students did a great job showing it can be transformed into a playful material,” Heiss said. “Their products are not only well designed but would also make perfect holiday gifts.”

The National Museum of Industrial History is located at 602 E. Second St., Bethlehem.

Hours are 10 a.m. to 5 p.m. Wednesday-Sunday, with extended hours until 7 p.m. Fridays and Saturdays through Dec. 23.

Posted on: