A step toward dye- and chemical-free color filters

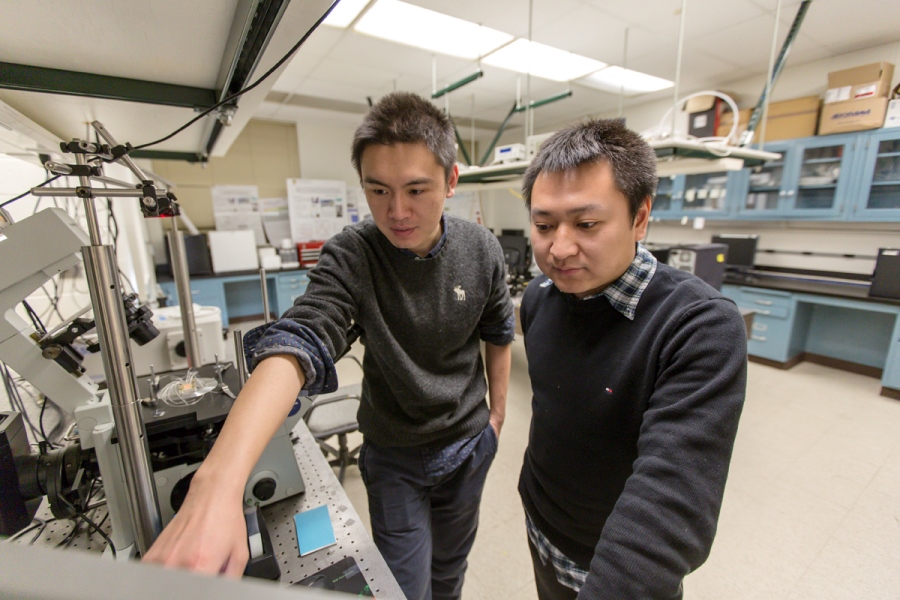

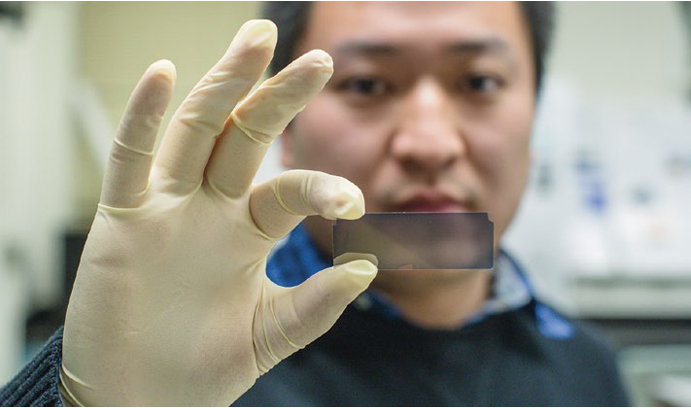

The key to the improved transmission efficiency in Ph.D. candidate Beibei Zeng’s plasmonic color filters is the ability to tune the dimensions of the nanostructures on an ultrathin metal film.

TVs, iPads and other devices use filters to display the breadth of colors available in the visible portion of the electromagnetic spectrum. Conventional color filters are typically made of organic dyes or chemicals, but they can be damaged by heat and ultraviolet radiation (UVR), and they are costly to make.

For these reasons, says Beibei Zeng, engineers are turning to plasmonic color filters (PCFs), which are based on surface plasmons, or the collective oscillation of electrons at metal/dielectric interfaces. These filters are made by fabricating, on a thin metal film, arrays of holes with diameters of 10nm or less. By varying the geometry of these nanoholes, it is possible to create a broad spectrum of colors for imaging applications.

“PCFs,” says Zeng, a Ph.D. candidate in electrical engineering, “are simple to make and easily tuned over a wide range of colors. They are very stable and they are not vulnerable to damage from heat, humidity or UVR.”

The efficiency with which PCFs transmit light is only about 30 percent—less than half the rate for conventional color filters. Zeng’s team has developed a new PCF scheme that achieves a transmission efficiency of 60 to 70 percent by relying on a subtractive filtering approach.

Subtractive color filters (SCFs) are used in image sensors, says Zeng. They have advantages over additive filters in color signal strength and light transmission, but researchers have not yet been able to produce high-performance plasmonic SCFs.

Zeng’s group more than doubled the transmission efficiency of PCFs by fabricating the filters onto a 30nm-thick silver film patterned with 1D nanogratings. Additive PCFs are typically etched onto 200nm-thick films.

“The relative thinness of our filters causes a coupling in the electromagnetic resonances at the top and the bottom of the metal surface,” says Zeng. “This does not occur with thicker metal films. Without this coupling, a transmission peak occurs; with it, the peak becomes a valley and causes a transmission dip.

“We can control this transmission dip by tuning the dimensions of the nanostructures on the metal film. Just a few years ago, we could not fabricate such thin structures. Now we can fabricate nanostructures systematically and achieve fine control of the colors transmitted through nanostructured films.”

The group reported its results in a paper titled “Ultrathin Nanostructured Metals for Highly Transmissive Plasmonic Subtractive Color Filters,” which was published by Scientific Reports, a Nature publication. The paper was written by Zeng; Filbert J. Bartoli, department chair of electrical and computer engineering; and Yongkang Gao ’14 Ph.D.

Posted on: